MPC Control

MPC Controller Overview

The MultiProtoCol (MPC) Heat Pump controller is designed to allow the integration of water source heat pump equipment into DDC systems. The MPC Controller has the ability to communicate through a choice of three widely used protocols: BACnet MS/TP, Johnson Controls N2, and Modbus. The protocol of choice for the particular system is selected by simply configuring DIP switches on the MPC Controller. This flexibility allows one controller, the MPC, to be used in a multitude of buildings which use any of these three common protocols.

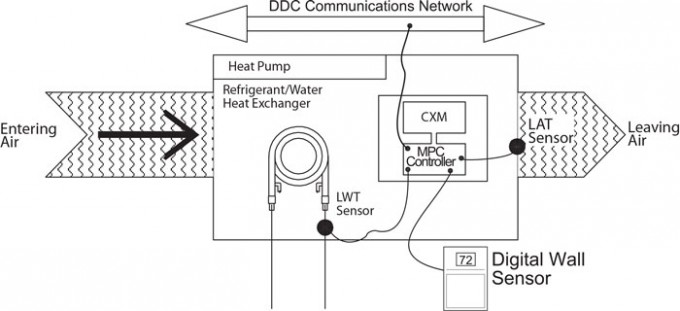

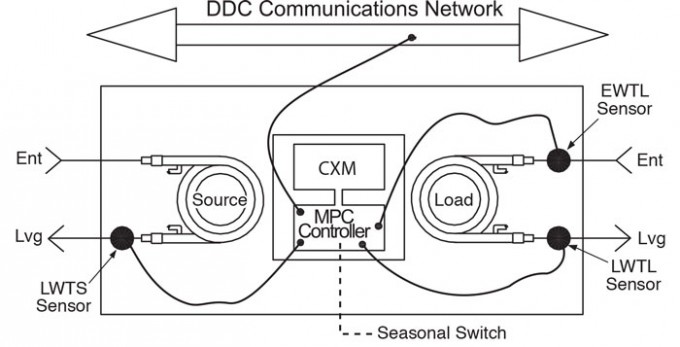

The MPC serves as a node of information processing between the heat pump and the DDC network. See Figure below. The MPC commands the heat pump to heat and cool based upon sensor inputs. The MPC then monitors operation of the heat pump and communicates the operating parameters to the DDC network. The MPC will always work in conjunction with a CXM or DXM controller, which also resides in the heat pump control box. The MPC has factory pre-loaded application software which allows optimal control of the heat pump equipment. The MPC can run in stand-alone operation as well as with the DDC network. Therefore, when the heat pump arrives at the jobsite with the factory installed MPC Controller, the heat pump is ready to run stand-alone and then can be connected to the DDC network at any time.

Typical System for MPC Controller Water-to-Air Heat Pump

Water-to-Water Heat Pump

FEATURES & BENEFITS

Multi-Protocol communications provides DDC

system flexibility.

- Supports native BACnet MS/TP communications (the ASHRAE standard protocol for interoperability).

- Supports Johnson Controls N2 communications (for integration into Johnson Controls Metasys DDC systems).

- Supports Modbus communications for integration into Modbus DDC networks.

- Four baud rate levels offer flexible communications speeds of 9600, 19.2k, 38.4k, or 76.8k baud.

- Employs a 16-bit bus Hitachi processor with 512kB RAM and 1024kB Flash Memory which allows, if needed, MPC programs to be upgraded and easily downloaded in the field.

- Removable field wiring connectors for ease of field service.

- Engineered for quality and reliability

- Enables building operators to easily upgrade firmware in the future.

ClimateMaster, Inc.

7300 S.W. 44th Street

Oklahoma City, OK 73179

(405)745-6000

Learn more about other Climate Control Group companies

CCG | ClimaCool | ClimateCraft | IEC

© ClimateMaster, Inc. All rights reserved 2024